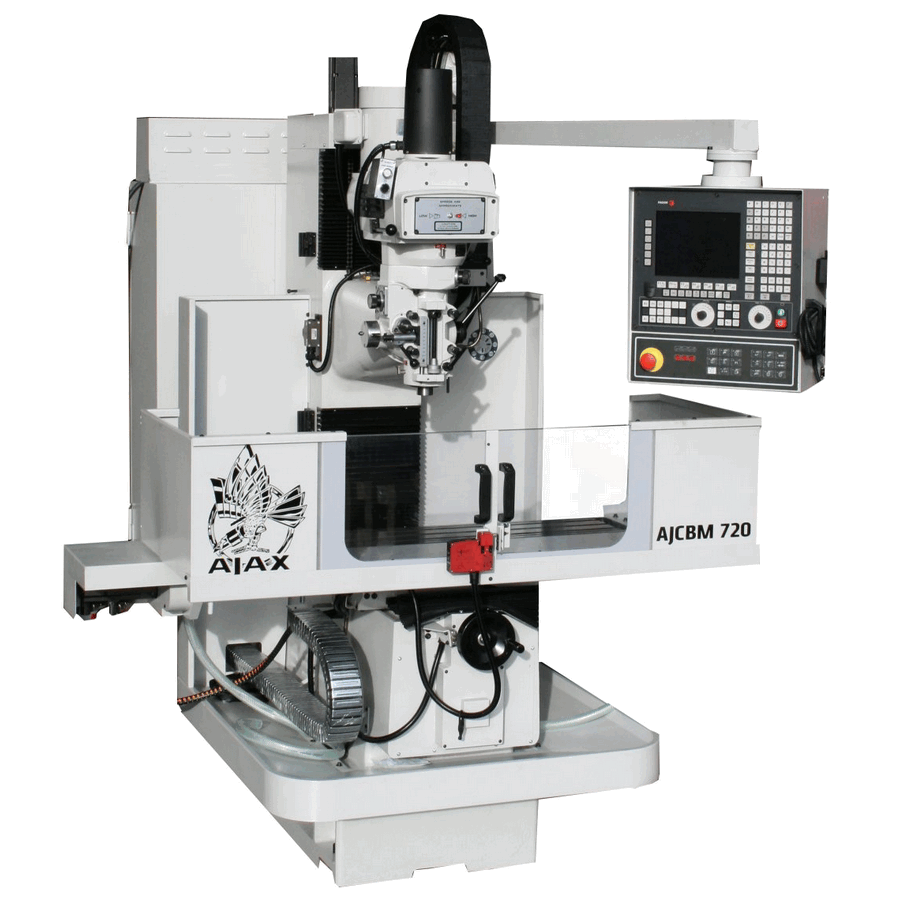

Interactive CNC Vertical Bed Mills.

Ajax CNC Bed Milling Machines

Bridging the Gap Between Turret Mills and Machining Centres

The Ajax range of CNC bed milling machines is designed to deliver substantial machining capacity at a highly competitive price—filling the gap between small turret mills and full-size bed mills.

Engineered as a modern replacement for the Bridgeport Interact, these machines are equipped with reliable Heidenhain CNC controls, offering precision, ease of use, and proven performance.

Decades of Expertise You Can Trust

Ajax has been supplying CNC bed mills since the earliest days of CNC adoption in the 1980s. With decades of experience, we understand the needs of workshops requiring flexibility, reliability, and accuracy in a compact footprint.

Faster Setup, Smarter Design

Thanks to their open-bed design, Ajax CNC bed mills are easier and quicker to set up than traditional machining centres—making them ideal for:

- One-off components

- Prototype work

- Small batch production

The open layout allows for excellent visibility and accessibility, enabling operators to achieve high accuracy with minimal setup time.

Engineered for Strength, Stability, and Precision

The main structural components of the machine are constructed from high-grade cast iron, ensuring exceptional rigidity and long-term stability during heavy-duty operations.

All slideways are hardened, ground, and coated with Turcite-B for reduced friction and smooth movement. Combined with high-precision ballscrews, this setup delivers outstanding accuracy, repeatability, and surface finish.

Every machine is CE and CA marked, meeting strict international standards for safety and compliance.

Talk to Our Experts

Need help choosing the right solution for your workshop?

Call one of our experienced sales engineers today to discuss your specific requirements.

For more information about control systems, please click here.

High Precision Calibrated with Renishaw laser.

All are machines are high precision calibrated using a Renishaw laser to give us super high precision. We then check this and all the alignments with the Renishaw Ballbar system which checks the machine while it is performing a circular move in 2 axis.

Specifications

Standard Features.

- Fagor 8058 elite with simple conversational programming.

- Heidenhain TNC 320 conversational programming.

- Siemens 828D with shopmill conversational programming.

- Fanuc 0i MF Plus Control with Manual Guide i conversation programming.

- Control manufactures AC Servo motors.

- Turcite B Coated hardened & ground slides.

- Automatic lubrication.

- LED work light.

- Slide-way covers.

- Rigid construction.

- Good ergonomic design.

- Interlocked Table guards.

- Power drawbar.

- CE / CA mark.

Optional accessories.

- Full enclosed guards.

- Tooling packages.

- Clamp Kits.

- Machine vices.

Precision You Can Measure – Backed by Renishaw Laser Technology

At Ajax, precision is not just a promise—it’s a measurable standard. We are proud to be one of the few companies in the UK equipped with the Renishaw XL-80 laser measurement system, a state-of-the-art device capable of detecting motion with nanometre-level accuracy—that’s one-thousandth of a micron or a millionth of a millimetre.

This industry-leading technology allows us to calibrate our machines with extraordinary precision, ensuring they consistently meet the highest performance standards. Calibration can be carried out on-site, and we recommend annual recalibration to maintain peak accuracy and long-term reliability.

Our standard calibration results typically guarantee machine performance within an exceptional tolerance of ±0.002 mm across the entire working envelope. In comparison, many competitors lack both the equipment and capability to verify their tolerances—often relying on unsubstantiated claims rather than proven data.

With Ajax, you’re not just getting machinery—you’re investing in verifiable, certified precision.

Let me know if you’d like this expanded into a full “Quality Assurance” or “Why Choose Ajax” page with visual elements or additional sections on service and support.

Applications

The CNC Bed Milling Machines can be used for many applications in tool-rooms, machine shops, fabrication shops and production shops. For milling, drilling and boring with much easier set up than on a VMC the AJCBM range hit the mark for all types of precision work.

Delivery, Installation & Training – We’ve Got You Covered

Our trusted delivery partners can transport and offload your machine using a variety of methods tailored to your site—whether that’s with a Versa-Lift or machine skates for precise positioning.

Once the machine is in place, our fully trained engineers will:

- Level and commission the machine

- Ensure everything is running correctly and safely

- Provide comprehensive training on operation and basic maintenance

From delivery to production, we support you every step of the way.

📞 Get in touch to arrange delivery and installation.