Heavy Duty Milling Machines.

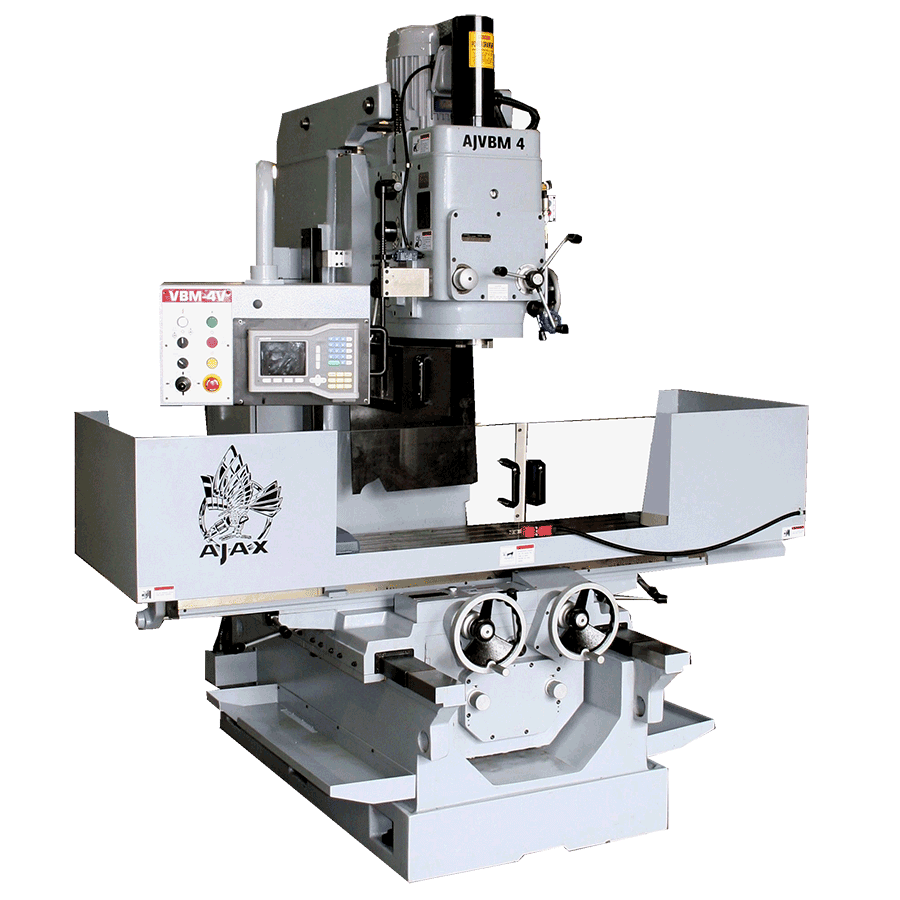

AJVBM Heavy-Duty Vertical Milling Machines

The AJVBM series from Ajax are robust, heavy-duty vertical milling machines, designed to handle demanding milling and boring applications with precision and reliability.

All axes are driven by low-friction ball screws, ensuring smooth operation, enhanced accuracy, and reduced wear over time. When not in use, axes are pneumatically clamped, providing maximum stability during machining.

Key safety features include fully interlocked guarding on both the table and spindle, ensuring operator protection and compliance with the latest safety regulations.

✔️ CE & CA Marked for international quality and safety compliance

✔️ Ideal for high-precision milling and boring in industrial environments

✔️ Engineered for stability, durability, and ease of operation

Engineered for Performance

Ajax AJVBM machines are large, heavy-duty vertical milling machines, purpose-built to handle large components with ease and precision. Designed and built by engineers, for engineers, these machines combine rugged construction with thoughtful engineering to deliver reliable, high-performance machining in demanding environments.

Specifications.

Precision Meets Performance

These machines are ergonomically designed, blending the latest engineering techniques with exceptional build quality to ensure long-term reliability and ease of use. With robust construction, precision components, and operator-focused features, we are proud to say that the Ajax AJVBM range represents some of the best vertical milling machines available on the market today.

Versatile Power and Durability

The AJVBM range features robust mechanical gearboxes, providing operators with a wide range of feeds and speeds to suit various machining tasks. All gears are hardened and ground for maximum durability, ensuring long service life and consistent performance even under demanding conditions.

Strength, Stability & Longevity

To ensure maximum strength and rigidity, our machines are built using heavy-duty ribbed castings. The wide slideways provide superior cutting stability, reducing deflection during heavy machining. An automatic lubrication system maintains consistent oil flow to all critical components, minimizing wear and extending the machine’s operational life.

Powerful Spindle Drive for Maximum Flexibility

The spindle motor features two-speed operation and is driven through a 12-speed gearbox, delivering exceptional torque and greater cutting power across a wide range of applications. For added versatility, the AJVBM8 model is equipped with an inverter-driven spindle, offering variable speed control for even greater flexibility and precision during demanding machining tasks.

Precision Axis Control and Durable Slideways

To provide a wider range of feed rates, all axes are inverter-controlled directly from the pendant, giving the operator flexible and precise control. The slideways are hardened and ground for durability, and lined with Turcite B anti-friction material to ensure smooth movement, reduced wear, and long-lasting accuracy.

Pendant Control.

The machine is controlled from a pendant mounted on an arm. With control of the spindle & axis for ease of use. If selected the DRO is also mounted here.

Optional Extras.

- 2 or 3 axis DRO.

- Clamping Kits.

- Machine vices 100, 150 or 200mm.

- Dividing head.

- Collet holder with collets.

- Boring head.

- Tooling packages.

Gallery.

Delivery, Installation & Training – We’ve Got You Covered

Our trusted delivery partners can transport and offload your machine using a variety of methods tailored to your site—whether that’s with a Versa-Lift or machine skates for precise positioning.

Once the machine is in place, our fully trained engineers will:

- Level and commission the machine

- Ensure everything is running correctly and safely

- Provide comprehensive training on operation and basic maintenance

From delivery to production, we support you every step of the way.

📞 Get in touch to arrange delivery and installation.