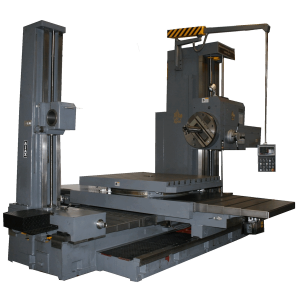

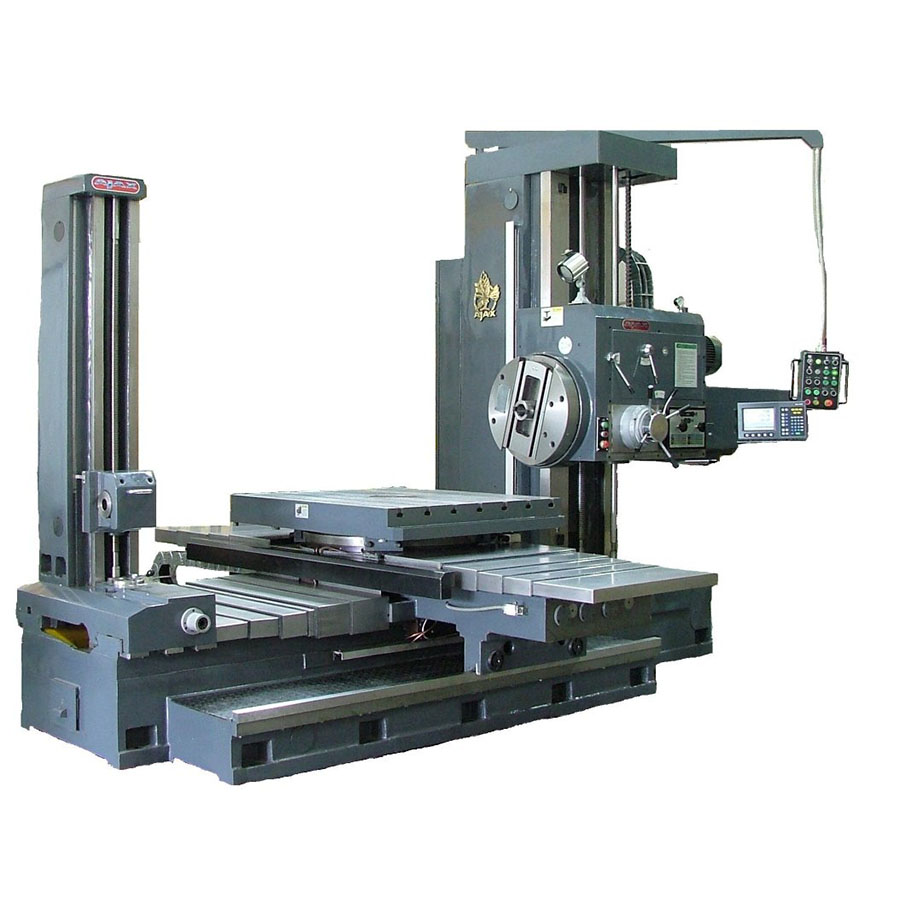

Ajax Horizontal Boring Machines.

Ajax range of Horizontal Boring Machines bring back the tradition of using one machine for many different aspects of machining. So any job with milling , drilling, boring & facing big & small work pieces.

Features include powered rotary table, power draw-bar, power feed and rapids, DRO options, optional tail stock, pendant control, telescopic slide-way covers, power clamping, automatic lube, pre-select speed changes along with heavy duty construction.

So our machines are suitable for all types of valves blocks and any multi sided machining job the horizontal borer makes it easier with less setting up and more machining. CE & CA Marked.

Options.

Tailstock for line boring, boring bars, Newall DRO systems.

Specifications.

Application.

These boring machines can be used for milling, drilling & boring. Some work pieces can be set up once, bored and milled on all 4 sides using the powered rotary table, which is a quicker operation. Drilling applications can be done easily using the quill before boring. So this gives more accuracy and ease of use.

Tail Stock.

Our tailstocks can be used for line boring, like the big end bearings of an engine keeping them all in line.

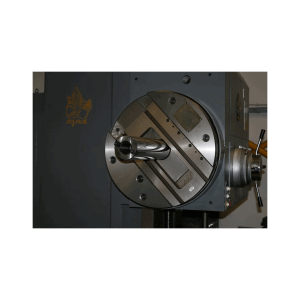

Headstock.

All headstocks are counterbalanced to give lightweight operation of the vertical travel of the head when un-clamped.

Gearboxes.

The gearboxes all pre-select, so you can dial in your next speed and feed, then press a button on the pendant to make the change. Also they are all running in oil baths to ensure they are fully lubricated.

Gears and Slides.

Because the machines gears are hardened & ground it gives quieter smoother operation and longer life.

With the slides & screws on the machine are automatically lubricated to give stable machining and longevity to the life of the machine.

Axis Drives.

All of the axis are driven from electromagnetic clutches selected from the control panel. The axis can be hand operated to fine position and have hydraulic clamps to give solid stable machining on all redundant axis. The active axis automatically un-clamped when selected for feeding by hand or auto feed.

Slides.

Our slideways are covered by steel guards to protect from swarf damage. Plus they are hardened & ground with turcite B anti friction material running against them.

Base.

The main base casting has multi leveling and bolting down points to give a stable platform, to keep accuracy.

Delivery and installation.

Our delivery companies can deliver your machine and offload it with a variety of ways. They either drive it in with a versa lift or skate it in to position. Once its there our fully trained engineers will level and commission it.