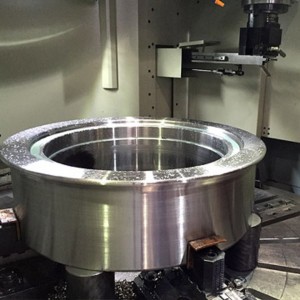

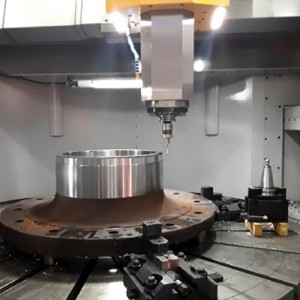

Ajax Vertical Turning Centres

The Ajax CNC Vertical Turning Centres are designed to be strong powerful & reliable, with a top Fanuc 0i TF Plus control, at an affordable price to help produce more and earn more. Fitted with automatic tool changer, fully enclosed guards & swarf conveyor as standard. With options of gearbox driven C axis and live tooling making this a real machine to be reckoned with. CE & CA Marked as standard.

Fitted with industry leading Fanuc 0i TF Plus CNC control system giving ultimate control & reliability, this can be upgraded to the Manual Guide i version with fully conversational control and full 3D graphics to make even the hardest job easy. So give us a call to discuss your VTL requirement.

For more information about control systems, please click here.

High Precision Calibrated with Renishaw laser.

Specifications

Features Include.

- Solid construction.

- High power stock removal.

- 12 station High Speed Tool changer.

- Fanuc 0i TF Plus control.

- Heavy duty guideways.

- Swarf conveyor.

Options.

- Manual guide i (Fanuc).

- Live Tooling & C Axis.

- CF Axis.

Standard Features.

- Fanuc 0i TF CNC control.

- Fully enclosed guarding & chip collection system.

- Swarf conveyor, coolant equipment.

- Automatic lubrication of bed ways.

- Electronic hand-wheel for X & Z Axes.

- Variable speed to include constant surfacing speed.

- Fanuc AC spindle drive.

- Fanuc Digital Feed drives & motors.

- Feed override control.

- High power lighting.

- Instruction manual.

Details.

The range of CNC Vertical Turning Centres are designed to meet the new demands of industry. Featuring top FANUC 0i TF control with the optional Manual Guide, the VTC can be programmed to produce any complicated component. Also available with live tooling & C axis.

Also featuring a solid cast bed and base the VTC is a powerfully stable machine, which can take large cuts and perform well with any material.

Accuracy

Accuracy is very important here at Ajax we are one of very few companies in the UK who have a Renishaw XL80 laser measurement machine. It can measure down to a Nano of movement which is a 1,000 ‘th of a Micron which is 1,000 ‘th of a Millimetre. We then use this data to calibrate the machine down to very high accuracy. We can do this on your site if required and re do this on an annual basis to keep your machine accurate. Our normal results get machines over the entire working envelope down to less than +/- 0.002 most of our competitors are way over this and cannot test it or prove it.

Calibration

All are machines are high precision calibrated using a Renishaw laser to give us super high precision, we then check this and all the alignments with the Renishaw Ballbar system which checks the machine while it is performing a circular move in 2 axis.

Ajax turning the world around.

Delivery & Installation

Our delivery companies can deliver your machine and offload it with a variety of ways. Then either drive it in with a versa lift or skate it in to position. Then once its there our fully trained engineers will level and commission it. Once this is done we will train you in its operation.