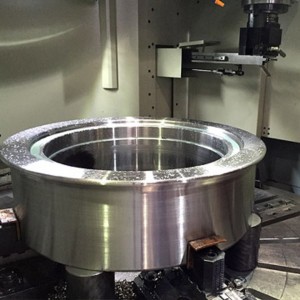

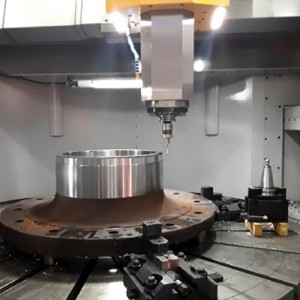

Ajax Vertical Turning Centres.

Ajax CNC Vertical Turning Centres are engineered for robustness, efficiency, and reliability. Designed to boost productivity and profitability, they come equipped with the advanced Fanuc 0i TF Plus control system—all at a competitive price point.

Standard features include:

- Automatic tool changer

- Fully enclosed safety guards

- Swarf conveyor

To further enhance performance, optional upgrades are available, such as:

- Gearbox-driven C axis

- Live tooling capabilities

Built to exacting standards, these machines are CE and CA certified, ensuring compliance and safety. With their powerful configuration and precision engineering, Ajax Vertical Turning Centres are the smart choice for demanding machining operations.

Fitted with the industry-leading Fanuc 0i TF Plus CNC control system, this machine delivers exceptional control and reliability. For enhanced functionality, it can be upgraded to the Manual Guide i version, which features fully conversational programming and full 3D graphical interface—making even the most complex tasks easier to manage.

Contact us today to discuss your Vertical Turning Lathe (VTL) requirements and discover how Ajax can support your production goals.

For more information about control systems, please click here.

High Precision Calibrated with Renishaw laser.

Specifications

Features Include.

- Solid construction.

- High power stock removal.

- 12 station High Speed Tool changer.

- Fanuc 0i TF Plus control.

- Heavy duty guideways.

- Swarf conveyor.

Options.

- Manual guide i (Fanuc).

- Live Tooling & C Axis.

- CF Axis.

Standard Features.

- Fanuc 0i TF CNC control.

- Fully enclosed guarding & chip collection system.

- Swarf conveyor, coolant equipment.

- Automatic lubrication of bed ways.

- Electronic hand-wheel for X & Z Axes.

- Variable speed to include constant surfacing speed.

- Fanuc AC spindle drive.

- Fanuc Digital Feed drives & motors.

- Feed override control.

- High power lighting.

- Instruction manual.

Details.

The range of CNC Vertical Turning Centres is designed to meet the new demands of industry. Featuring the top FANUC 0i TF control with an optional Manual Guide, the VTC can be programmed to produce any complex component. It is also available with live tooling and a C axis.

Also featuring a solid cast bed and base, the VTC is a powerfully stable machine that can handle large cuts and perform well with any material.

Accuracy

At Ajax, precision is paramount. We proudly stand out as one of the few companies in the UK equipped with a Renishaw XL80 laser measurement machine, capable of detecting movements as minute as a nanometre—equivalent to one-thousandth of a micron or one-thousandth of a millimetre. We utilize this precise data to calibrate our machines to exceptional accuracy. This calibration can be performed on-site if needed, and we recommend annual recalibrations to maintain optimal performance. Typically, our results ensure that machines operate within an impressive tolerance of less than +/- 0.002 across their entire working range. In contrast, many of our competitors fall short of this standard and lack the means to verify their claims.

Ajax turning the world around.

Delivery, Installation & Training – We’ve Got You Covered

Our trusted delivery partners can transport and offload your machine using a variety of methods tailored to your site—whether that’s with a Versa-Lift or machine skates for precise positioning.

Once the machine is in place, our fully trained engineers will:

- Level and commission the machine

- Ensure everything is running correctly and safely

- Provide comprehensive training on operation and basic maintenance

From delivery to production, we support you every step of the way.

📞 Get in touch to arrange delivery and installation.