Vertical Boring Machines.

Ajax Vertical Boring & Turning Machines

Precision Turning for Heavy-Duty Components

The Ajax range of Vertical Boring and Turning Machines is specifically designed for large, heavy workpieces where traditional horizontal lathes fall short. With gravity working in your favour, these machines make setup easier, safer, and more efficient—especially when handling large or awkwardly shaped components.

Engineered for Performance

Our latest models include advanced features that enhance usability without the complexity of full CNC systems:

✅ Servo-Driven Ballscrews on the X and Z axes for accurate, smooth movement

✅ Handwheel Control for intuitive manual operation and setup

✅ VFD-Controlled Spindle allows near-zero speed rotation—perfect for clocking in components

✅ Simplified Operation offering CNC-like benefits with manual ease

Whether you’re managing heavy-duty turning jobs or want the flexibility to upgrade to CNC later, these machines are built to deliver.

Optional CNC Models Available

For applications requiring automation, we also offer this range in full CNC configurations, giving you maximum flexibility and scalability.

📞 Call us today or

📧 Email sales@ajax-mach.co.uk

Let’s talk about your turning and boring requirements.

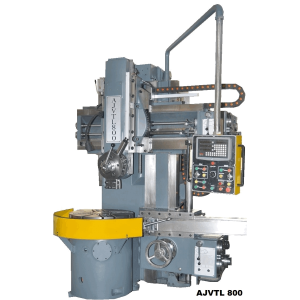

Ajax Vertical Turning Lathe (VTL)

Engineered for Efficiency, Designed for Heavy-Duty Turning

The Ajax Vertical Turning Lathe features a horizontally oriented chuck face, making it easier to load heavy components while leveraging gravity for improved stability during machining. This design is ideal for large and heavy workpieces that are difficult to handle on conventional lathes.

Robust Construction & High-Precision Components

- Heavy-Duty Cast Iron Frame for maximum rigidity and vibration damping

- 4-Jaw Chuck with De-Mountable Jaws, supported by high-precision NSK spindle bearings for smooth rotation and long-term accuracy

- Main Turret feeds vertically at 90°, with adjustable angles of up to ±30°, offering versatility for complex turning tasks

- Rail-Mounted Design allows the turret to move closer to the workpiece, improving rigidity and cutting performance

Side Head for Additional Machining Flexibility

- Equipped with a side-mounted headstock featuring a 4-way tool post

- Provides vertical elevation and horizontal feed for efficient side turning applications

Operator-Friendly Control

- Pendant Control Station with joystick-operated feed and rapid traverse functions

- Pre-Select Hydraulic Speed Control for smooth, responsive adjustments during operation

All machines are CE & CA marked, ensuring compliance with international safety and quality standards.

📞 Talk to our team today to discuss how the Ajax VTL can enhance your heavy-duty machining operations.

📧 Email: sales@ajax-mach.co.uk

Specifications.

Gallery.

Why Choose a Vertical Boring & Turning Machine?

Harness Gravity. Maximise Efficiency.

Vertical boring and turning machines are incredibly versatile—making them the ideal choice for handling large, heavy turning jobs. Unlike traditional horizontal lathes, where gravity works against you during setup, vertical machines use gravity to your advantage, simplifying the loading and positioning of bulky workpieces.

This natural benefit results in:

- Easier setup and alignment

- Greater stability during machining

- Improved safety and operator efficiency

A Valuable Addition to Any Machine Shop

Whether you’re expanding your capacity or upgrading your capabilities, an Ajax vertical boring and turning machine is a smart investment. Engineered for strength, precision, and ease of use, it’s ready to handle your toughest turning challenges.

📞 Speak with one of our experts today to see how this machine can improve your workflow.

📧 Email: sales@ajax-mach.co.uk

Delivery, Installation & Training – We’ve Got You Covered

Our trusted delivery partners can transport and offload your machine using a variety of methods tailored to your site—whether that’s with a Versa-Lift or machine skates for precise positioning.

Once the machine is in place, our fully trained engineers will:

- Level and commission the machine

- Ensure everything is running correctly and safely

- Provide comprehensive training on operation and basic maintenance

From delivery to production, we support you every step of the way.

📞 Get in touch to arrange delivery and installation.