Ajax Horizontal Boring Machines.

Ajax Horizontal Boring Machines

Versatility, Tradition, and Precision in One Machine

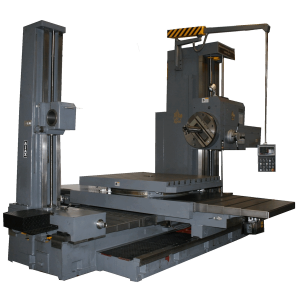

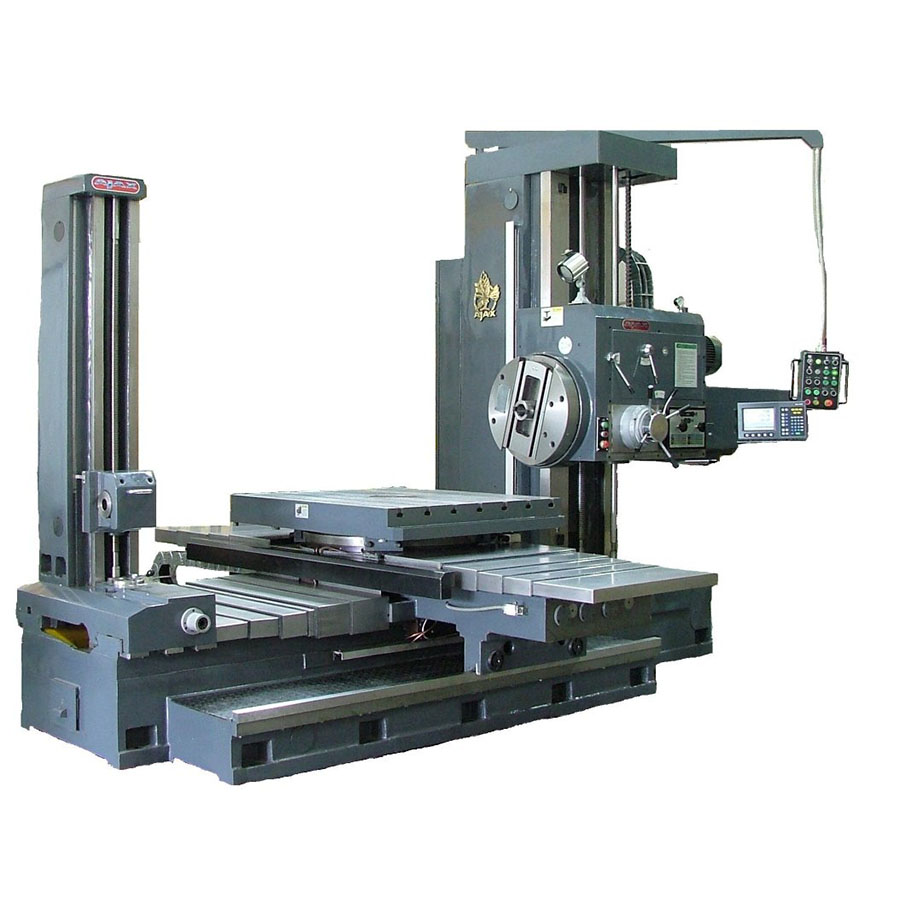

The Ajax range of Horizontal Borers brings back the time-honoured tradition of using one machine for multiple machining operations—combining flexibility, efficiency, and precision in a single package.

Whether you’re handling large or small workpieces, Ajax horizontal borers are perfectly suited for a variety of operations, including:

- ✅ Milling

- ✅ Drilling

- ✅ Boring

- ✅ Facing

These machines are built for multi-purpose performance, making them ideal for workshops looking to maximise productivity and minimise setup times. With rugged construction and advanced features, they offer exceptional value across a wide range of industries.

Key Features of Ajax Horizontal Borers

Engineered for Performance, Built for Heavy-Duty Work

Our horizontal boring machines come packed with features designed to simplify complex machining tasks, reduce setup time, and increase productivity:

- ✅ Powered Rotary Table – For flexible multi-sided machining

- ✅ Power Draw-Bar – For quick and secure tool changes

- ✅ Power Feed & Rapids – Enhances efficiency and precision

- ✅ DRO Options – Digital accuracy at your fingertips

- ✅ Optional Tailstock – For additional support with long workpieces

- ✅ Pendant Control – Ergonomic operation and monitoring

- ✅ Telescopic Slideway Covers – Protects components, reduces wear

- ✅ Power Clamping – Fast, secure workpiece clamping

- ✅ Automatic Lubrication – Reduces maintenance, extends life

- ✅ Pre-Select Speed Changes – Streamlines operations

- ✅ Heavy-Duty Construction – Built to last under demanding conditions

These machines are ideal for machining valve blocks, large components, and any multi-sided job where precision and minimal setups are essential. The horizontal borer excels in versatility—giving you more time machining and less time setting up.

CE & CA Marked to meet international safety and quality standards.

Optional Enhancements for Ajax Horizontal Borers

Expand Your Capability. Improve Your Precision.

To tailor your Ajax Horizontal Borer to your exact requirements, we offer a range of high-performance options:

- ✅ Tailstock for Line Boring – Adds critical support for long or heavy workpieces during precision line boring operations

- ✅ High-Quality Boring Bars – Engineered for rigidity and accuracy across a wide range of applications

- ✅ Newall Digital Readout (DRO) Systems – Industry-leading precision with easy-to-read, robust digital displays for improved measurement accuracy and repeatability

These enhancements ensure that your horizontal borer is fully equipped for demanding, high-accuracy applications across industries—from valve manufacturing to heavy fabrication.

Looking for a tailored solution? Get in touch with our engineers to configure the perfect setup for your machining needs.

📧 Email: sales@ajax-mach.co.uk

📞 Call us today. Let’s build the machine that works for you.

Specifications.

Versatile, Efficient, and Built for Precision

Ajax horizontal boring machines are engineered for multi-purpose machining—including milling, drilling, and boring—in a single setup. With the powered rotary table, complex components can be accurately bored and milled on all four sides without the need for multiple re-fixtures, dramatically reducing setup time and boosting productivity.

The quill system allows for precise drilling operations before boring, increasing both accuracy and ease of use. This all-in-one capability makes Ajax boring machines ideal for demanding applications where precision, efficiency, and flexibility are essential.

Tailstock for Precision Line Boring

Our robust tailstocks are ideal for line boring operations, such as aligning big end bearings on engine blocks, ensuring they remain perfectly in line. This feature is essential for maintaining precision, structural integrity, and smooth operation in high-performance assemblies.

Counterbalanced Headstocks

All headstocks are fully counterbalanced to ensure smooth and lightweight vertical movement when unclamped, making adjustments quick, safe, and effortless.

Pre-Select Gearboxes with Oil Bath Lubrication

All gearboxes feature a pre-select function, allowing you to dial in the next speed and feed setting in advance—simply press a button on the pendant to activate the change. Each gearbox runs in a fully sealed oil bath to ensure constant lubrication and long-term reliability.

Smooth, Quiet Operation and Long-Term Reliability

The machine’s gears are hardened and ground to ensure smoother, quieter operation and significantly extended service life. Additionally, all slides and screws are automatically lubricated via a central lubrication system, providing consistent performance, stable machining, and enhanced longevity of the machine.

Precision Axis Control with Electromagnetic Clutches

All axes are driven via electromagnetic clutches, which are selected directly from the control panel for ease of use. Each axis can also be hand-operated for fine positioning. Hydraulic clamps are fitted on all redundant axes to ensure solid and stable machining. When an axis is selected for manual or automatic feed, it is automatically unclamped, enabling smooth and precise movement.

Protected and Precision-Guided Slideways

All slideways are protected by durable steel guards to prevent swarf damage during operation. They are hardened and ground for maximum wear resistance and longevity. For smooth, low-friction movement, Turcite B anti-friction material is used, ensuring precise and reliable axis travel.

Base

Stable Foundation for Lasting Accuracy

The main base casting features multiple levelling and bolting points, providing a stable and rigid platform essential for maintaining precision and accuracy throughout the machine’s lifetime.

Delivery, Installation & Training – We’ve Got You Covered

Our trusted delivery partners can transport and offload your machine using a variety of methods tailored to your site—whether that’s with a Versa-Lift or machine skates for precise positioning.

Once the machine is in place, our fully trained engineers will:

- Level and commission the machine

- Ensure everything is running correctly and safely

- Provide comprehensive training on operation and basic maintenance

From delivery to production, we support you every step of the way.

📞 Get in touch to arrange delivery and installation.