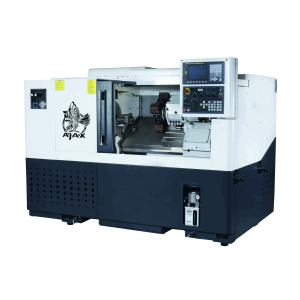

Ajax Ace Production Slant Bed CNC Lathes.

Ajax Ace Production Slant-Bed CNC Lathes

Power, Precision & Productivity – Built for the Future

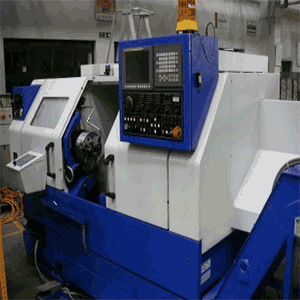

The Ajax Ace range of Production Slant-Bed CNC Lathes is engineered to deliver strength, reliability, and high-performance machining—all at a highly competitive price. Fitted with the advanced Fanuc 0i TF Plus CNC control, these machines help you produce more and earn more with confidence.

Enhanced Capabilities for Modern Production

New models are now available with:

- Y-axis functionality for complex milling operations

- Sub-spindle options to complete parts in a single setup

Whether you’re handling large volumes or precision components, the Ajax Ace delivers speed, flexibility, and accuracy.

Built for a Sustainable Future

Our production methods are as forward-thinking as our machines. The Ajax Ace lathes are manufactured in an environmentally conscious facility, where roof-mounted solar panels provide clean, renewable energy—even powering the casting plant itself.

By choosing Ajax, you’re not only investing in productivity—you’re supporting a more sustainable manufacturing future.

Talk to Our Experts

Ready to boost your production capability?

Call or email our experienced engineers today to discuss your machining requirements and find the perfect Ajax solution for your workshop.

CNC Control Options

Advanced CNC Control for Maximum Flexibility and Ease of Use

Every Ajax machine is equipped with industry-leading CNC control systems for unmatched precision and reliability. Choose from:

- Fanuc 0i TF Plus

- Siemens 828D ShopTurn

The Fanuc 0i TF Plus can be upgraded to the Manual Guide i version, offering:

- Fully conversational programming for quick, intuitive operation

- Advanced 3D graphics for clear visualisation of complex machining processes

This enhanced interface makes even the most demanding tasks easier to manage—ideal for both experienced machinists and those new to CNC technology.

Built on a rigid cast-iron bed and base with inset hardened steel guideways, the Ajax Ace offers exceptional structural stability. This robust construction allows for heavy-duty cutting and consistently high performance across all types of material.

To ensure uncompromising accuracy, every Ajax machine undergoes precision calibration using the Renishaw XL-80 laser system. Final verification is performed with the Renishaw Ballbar, which measures circular interpolation across two axes to validate geometric precision and alignment.

All machines are CE and CA marked as standard, reflecting our commitment to safety, quality, and regulatory compliance.

Specifications

Standard Features.

- Fanuc 0i TF Plus CNC.

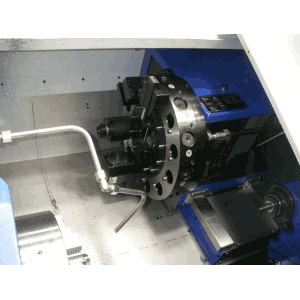

- Automatic multi station bi-directional turrets.

- Fully enclosed guarding & chip collection system.

- Coolant equipment.

- Automatic lubrication of bed ways.

- Electronic hand-wheel for X & Z Axes.

- Variable speed to include constant surfacing speed.

- Fanuc AC spindle drive.

- Fanuc Digital Feed drives & motors.

- High power LED lighting.

- Feed override control.

- Instruction manual.

Options.

- Bar feed systems.

- Live tooling options with C axis.

- Siemens 828D control.

- Manual Guide i (Fanuc)

- Swarf conveyor.

- Tool measuring probe.

Precision You Can Measure – Backed by Renishaw Laser Technology

At Ajax, precision is not just a promise—it’s a measurable standard. We are proud to be one of the few companies in the UK equipped with the Renishaw XL-80 laser measurement system, a state-of-the-art device capable of detecting motion with nanometre-level accuracy—that’s one-thousandth of a micron or a millionth of a millimetre.

This industry-leading technology allows us to calibrate our machines with extraordinary precision, ensuring they consistently meet the highest performance standards. Calibration can be carried out on-site, and we recommend annual recalibration to maintain peak accuracy and long-term reliability.

Our standard calibration results typically guarantee machine performance within an exceptional tolerance of ±0.002 mm across the entire working envelope. In comparison, many competitors lack both the equipment and capability to verify their tolerances—often relying on unsubstantiated claims rather than proven data.

With Ajax, you’re not just getting machinery—you’re investing in verifiable, certified precision.

Let me know if you’d like this expanded into a full “Quality Assurance” or “Why Choose Ajax” page with visual elements or additional sections on service and support.

Delivery, Installation & Training – We’ve Got You Covered

Our trusted delivery partners can transport and offload your machine using a variety of methods tailored to your site—whether that’s with a Versa-Lift or machine skates for precise positioning.

Once the machine is in place, our fully trained engineers will:

- Level and commission the machine

- Ensure everything is running correctly and safely

- Provide comprehensive training on operation and basic maintenance

From delivery to production, we support you every step of the way.

📞 Get in touch to arrange delivery and installation.