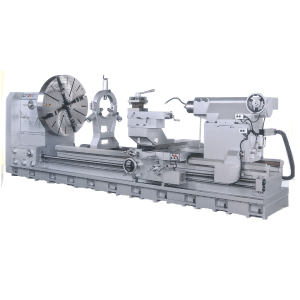

Heavy Duty Centre Lathes.

Heavy-Duty Universal Gap Bed Centre Lathes

Ajax offers a comprehensive range of heavy-duty universal gap bed centre lathes, with bed lengths of up to 8 metres and swing diameters up to 2,200 mm. This extensive capability ensures we can supply the exact lathe you need—whatever the size or scope of your turning application.

Engineered for Performance and Versatility

Our heavy-duty lathes are rigidly constructed and engineered to handle deep cuts in tough materials with ease. Designed for durability and precision, these machines are ideal for demanding industrial applications.

A wide range of optional features is available, including:

- Chucks (3 or 4-jaw)

- Steady rests

- Digital Readout (DRO) systems

- Taper turning attachments

- Tool posts and tool post grinders

This flexibility makes Ajax lathes capable of tackling virtually any turning task.

All machines are CE & CA marked, ensuring full compliance with international safety and quality standards.

Need help finding the right machine?

Speak with one of our experienced engineers today to discuss your specific requirements.

Main features include.

- Induction hardened and ground one piece beds with Turcite B antifriction slides.

- 4 way toolpost.

- Easily selected spindle speeds in geometric progression.

- Headstock gears are case hardened and “Reishauer” ground splined shafts which turn on roller bearings.

- The universal gearbox is totally enclosed and provides a range of metric or imperial threads.

- Saddle gearbox enables selection of feed to x and y axis, or to screw cutting and is available in left or right hand form.

- CE mark.

Options.

- 3 and 4 jaw chucks.

- Quick-change tool post.

- Fixed & Traveling Steadies,

- Revolving centres.

- Taper turning.

- Face Plates.

- 2 or 3 axis digital readouts.

Delivery, Installation & Training – We’ve Got You Covered

Our trusted delivery partners can transport and offload your machine using a variety of methods tailored to your site—whether that’s with a Versa-Lift or machine skates for precise positioning.

Once the machine is in place, our fully trained engineers will:

- Level and commission the machine

- Ensure everything is running correctly and safely

- Provide comprehensive training on operation and basic maintenance

From delivery to production, we support you every step of the way.

📞 Get in touch to arrange delivery and installation.