Gap Bed Centre Lathes.

Modern Engineering, Classic Craftsmanship

Built with a modern, proven design and faultless construction, our centre lathes meet the highest safety standards—exceeding both CE and HSE requirements. All machines are CE & CA marked as standard.

Inspired by the golden era of British engineering, from the likes of DSG, Colchester, Harrison, and Binns & Berry, our lathes are built the way machines used to be—using top-quality materials and assembled by experienced, skilled machine tool fitters.

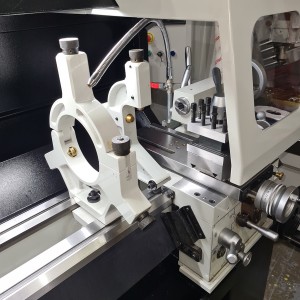

The AJL280, AJL330, and AJL380V lathes feature a double Vee slideway configuration, providing enhanced stability, improved accuracy, and superior long-term wear resistance.

Engineered for Performance and Longevity

Our centre lathes feature a wide range of spindle speeds driven by an inverter, providing full variable speed control to suit every application. With a comprehensive selection of feeds and screw-cutting options, these machines are designed to give you a clear advantage over the competition.

Backed by over 50 years of experience, Ajax lathes are built to run reliably for the next 20 years—without repair.

We also offer delivery, installation, and tailored training services to meet your specific needs.

📞 Contact one of our engineers today to discuss the perfect lathe for your workshop or training facility.

Specifications.

Main features include.

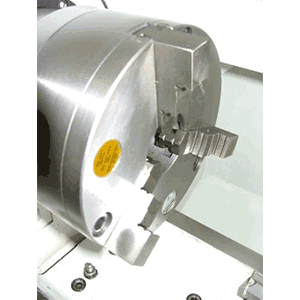

- 3 jaw precision chuck.

- High power LED work light built into the machine guard.

- Induction hardened and ground one piece beds with Turcite B antifriction coating.

- Easily selectable spindle speeds in geometric progression.

- Headstock gears are case hardened and ground splined shafts which turn on roller bearings.

- The universal feed gearbox is totally enclosed and provides a range of metric or imperial threads.

- Saddle gearbox enables selection of feed to x and y axis, or to screw cutting and is available in left or right hand form.

- CE & CA mark as standard.

Options.

- Bigger 3 jaw chucks.

- Quick change tool post with 4 holders.

- 4 jaw chuck options.

- Face plates.

- Steadies, centres and revolving centres.

- Taper turning.

- Grinding Attachment.

- Digital readouts.

- Tooling packages.

Quality from your Gap Bed Centre Lathe.

Our Commitment to Quality

At Ajax, we believe that quality still counts. That’s why we go above and beyond to supply machines that deliver exceptional precision and reliability. But we don’t stop there—because accuracy matters more than ever, every Ajax machine undergoes rigorous inspection and double-checking to ensure it meets our exacting standards before it reaches you.

When you choose Ajax, you’re choosing a partner dedicated to performance, precision, and long-term value.

.

Delivery, Installation & Training – We’ve Got You Covered

Our trusted delivery partners can transport and offload your machine using a variety of methods tailored to your site—whether that’s with a Versa-Lift or machine skates for precise positioning.

Once the machine is in place, our fully trained engineers will:

- Level and commission the machine

- Ensure everything is running correctly and safely

- Provide comprehensive training on operation and basic maintenance

From delivery to production, we support you every step of the way.

📞 Get in touch to arrange delivery and installation.