Ajax Hybrid Centre Lathe

AJAX Hybrid Turn Manual Centre Lathe with Automatic Cycles

Modern Precision with Classic Control

The AJAX Hybridturn Lathe replaces the manual centre lathe with a machine that can be used totally manually or with automatic cycles for block turning or screw cutting.

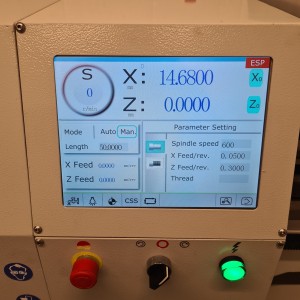

Equipped with a touch screen HMI (Human Interface) controlling a PLC to operate the machine. The cycles include straight turning & screw cutting. In the straight turning cycle you start at 0 then finish at -10mm and a depth of cut at 2mm, touch on the end of the part Z zero it and then tell it how far to go in Z. It will then take 5 cuts automatically removing 10mm & stop. If you then wanted to screw cut it, you tell it the pitch and how far to go in Z and press go. No changing gears on the speed, feed or screw cutting. It measures using glass scales from a DRO which makes it very accurate. This becomes the new norm for manual turning.

All machines are CE and CA marked, ensuring full compliance with international safety and quality standards.

Key features include:

- NSK spindle and thrust bearings for smooth, high-precision rotation

- Hardened and ground slideways to ensure long-term accuracy

- Automatic lubrication system for consistent maintenance-free operation

- Manual handwheels like on a manual lathe

- Joy stick control for manual feed operation

- High-power LED work lighting for enhanced visibility and safety

Specifications

Turning has become Easy

Introducing the all-new AJHY370 – A Modern Take on Turning

Experience an all-new style of machine that bridges the gap between manual and CNC turning. The AJHY370 puts control at your fingertips with a touchscreen interface for simple turning cycles, including:

- External Turning

- External Threading

- Internal Turning

- Internal Threading

All operations are managed by PLC control—no G-codes or complicated setups. Simply set your tool, enter your dimensions and cut data, and press Go.

This is a truly modern alternative to manual turning—but with the flexibility to use it as a manual machine as well. The digital readout is built directly into the touchscreen, allowing you to:

- Enter your feedrate directly on the screen instead of adjusting the gearbox and wasting time looking up feedrates on tables

- Use the joystick to feed manually in either axis

- Run parts as automated cycles

Safety & Convenience

- Full-width swing-down cover guard

- Chuck Guard

- 2 Emergency Stops

- Built-in work light

Key Specifications

- Centre height: 185mm

- Distance between centres: 950mm

- Swing over bed: 370mm

- Spindle bore: 55mm

- 2.2 KW variable-speed servo spindle motor with encoder feedback

- 200mm 3-jaw chuck

- Quick change tool post with 4 holders

- Coolant System

- 230V single-phase — plugs into a standard 3-pin socket

The AJHY370 is designed to make your work faster, safer, and more precise—without sacrificing the hands-on feel of manual turning.

Built on a Legacy of Innovation

The Hybridturn replaces the long-standing manual centre lathe (produced for 100’s of years) and the Quick Turn series. Our legacy dates back to the original Premier lathes, the first to feature Fagor 800T controls, followed by the 8055T. With over 20 years of experience in this machine category, Ajax stands at the forefront of hybrid manual/CNC turning solutions.

Standard Features.

- Touch screen HMI control.

- Interlocked guarding & chip collection system.

- 200mm 3 Jaw Chuck

- Hardened & ground slides to 400-450 HB.

- Coolant equipment.

- Automatic lubrication of bed ways.

- Hand-wheels or X & Z Axes.

- VFD Driven Spindle Motor

- High power LED lighting.

- Fixed centres & reducing bush.

- Quick Change Tool Post with 4 holders

- Instruction Manual.

Options.

- 4 Jaw chucks.

- Fixed & travelling steadies.

- Live centres.

- Face plates.

- Additional Tool Holders.

Delivery, Installation & Training – We’ve Got You Covered

Our trusted delivery partners can transport and offload your machine using a variety of methods tailored to your site—whether that’s with a Versa-Lift or machine skates for precise positioning.

Once the machine is in place, our fully trained engineers will:

- Level and commission the machine

- Ensure everything is running correctly and safely

- Provide comprehensive training on operation and basic maintenance

From delivery to production, we support you every step of the way.

📞 Get in touch to arrange delivery and installation.