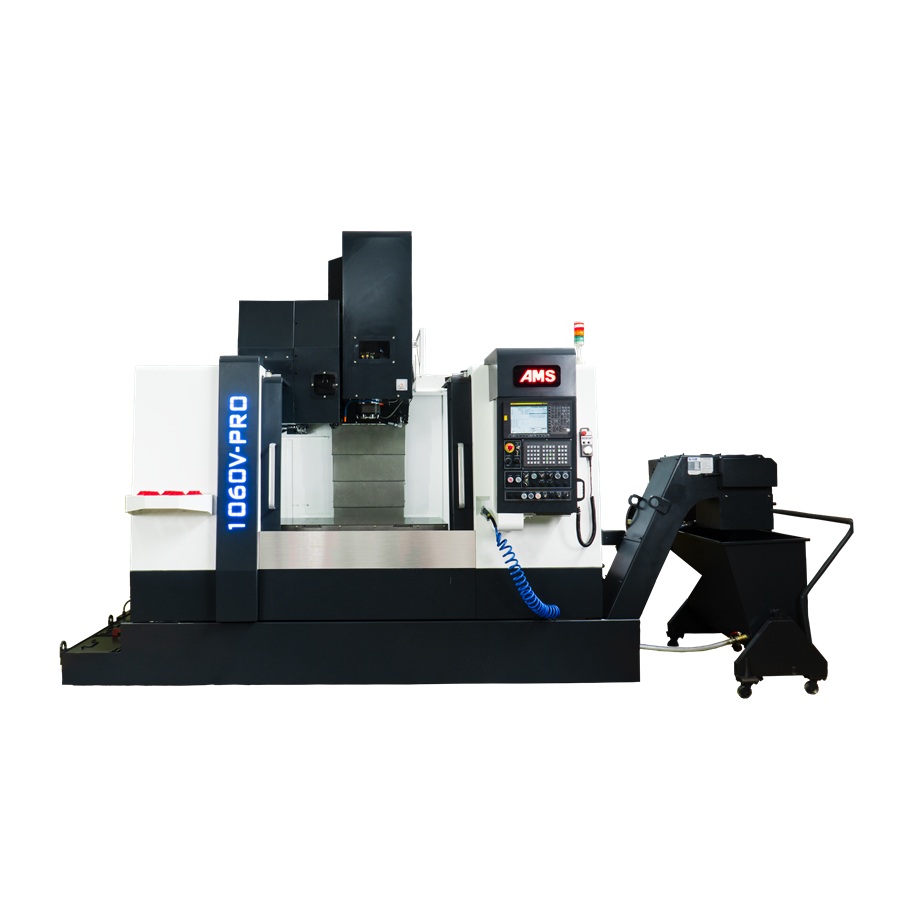

High Speed Vertical Machining Centres.

Ajax VMC V-Series Vertical Machining Centres

Built for Speed. Engineered for Quality.

The Ajax VMC V-Series vertical machining centres are built to exacting standards, using only the highest quality components to ensure performance, reliability, and durability.

The “V” stands for Velocity—because in modern manufacturing, speed matters. These machines are designed to deliver fast, precise machining that meets the demands of today’s high-output production environments.

Whether you’re handling complex components or high-volume runs, the Ajax V-Series delivers the performance, speed, and consistency your workshop needs.

Talk to the Experts

Ready to take your machining capabilities to the next level?

Call or email one of our experienced engineers today to discuss your requirements and discover how Ajax can support your success.

Ajax staff can advise on the best option for your workshop solutions. CE & CA Marked.

For more information about control systems, please click here.

High Precision Calibrated.

Precision Verified with Renishaw Technology

All Ajax machines are high-precision calibrated using the Renishaw XL-80 laser system, ensuring exceptional accuracy across the entire working envelope.

To verify this calibration and ensure perfect geometric alignment, we then use the Renishaw Ballbar system, which monitors machine performance during a circular interpolation movement across two axes.

This dual-stage verification process guarantees that every machine we supply meets the highest standards of precision and repeatability—delivering consistent results you can trust.

Specifications

Precision You Can Measure – Backed by Renishaw Laser Technology

At Ajax, precision is not just a promise—it’s a measurable standard. We are proud to be one of the few companies in the UK equipped with the Renishaw XL-80 laser measurement system, a state-of-the-art device capable of detecting motion with nanometre-level accuracy—that’s one-thousandth of a micron or a millionth of a millimetre.

This industry-leading technology allows us to calibrate our machines with extraordinary precision, ensuring they consistently meet the highest performance standards. Calibration can be carried out on-site, and we recommend annual recalibration to maintain peak accuracy and long-term reliability.

Our standard calibration results typically guarantee machine performance within an exceptional tolerance of ±0.002 mm across the entire working envelope. In comparison, many competitors lack both the equipment and capability to verify their tolerances—often relying on unsubstantiated claims rather than proven data.

With Ajax, you’re not just getting machinery—you’re investing in verifiable, certified precision.

Let me know if you’d like this expanded into a full “Quality Assurance” or “Why Choose Ajax” page with visual elements or additional sections on service and support.

Process

Machining processes can be performed at high speeds while maintaining reliable repeatability and quality. All models are built on cast columns and bases to eliminate vibration and enhance cutting finish. Rigid tapping is standard. The random tool changer utilizes an air blast to clean the spindle before the next tool enters, and the air blast is also used to clean the workpiece during machining.

Controls

Thus, bringing together the perfect balance of quality, reliability, and price, Ajax collaborates with Fanuc to install the Fanuc 0i MF Plus control. This system includes the option for Manual Guide i, making it easy to program in conversational form.

Siemens 828D available with the option of shopmill conversational software.

Ajax milling around the world.

Delivery, Installation & Training – We’ve Got You Covered

Our trusted delivery partners can transport and offload your machine using a variety of methods tailored to your site—whether that’s with a Versa-Lift or machine skates for precise positioning.

Once the machine is in place, our fully trained engineers will:

- Level and commission the machine

- Ensure everything is running correctly and safely

- Provide comprehensive training on operation and basic maintenance

From delivery to production, we support you every step of the way.

📞 Get in touch to arrange delivery and installation.