Ajax Superturn Flat Bed CNC Lathes

The New AJAX Superturn Range – Heavier, Stronger, Smarter

The new AJAX Superturn range is now heavier and more robust, designed for increased stability and cutting performance. Equipped with the latest Fanuc 0i TF Plus CNC control, these machines combine modern CNC capability with traditional manual usability.

They can be operated like a conventional manual lathe using electronic hand-wheels, with the CNC control functioning as a simple DRO (Digital Readout) system, making them perfect for both experienced machinists and new operators.

AJAX Superturn – Versatile, User-Friendly CNC Turning

The AJAX Superturn range is ideal for one-off parts and small batch production, thanks to its flexible electronic turning cycles. Programming is quick and intuitive—no prior CNC experience required.

Using the Fanuc control, users can easily create:

- Tapers

- Radii

- Grooves

- Multi-point profiles

- Screw cutting

—all by simply answering guided prompts directly on the screen. These conversational cycles can then be seamlessly linked into a complete program, offering both speed and convenience.

For more complex components or batch production, the Fanuc 0i Plus Turn Mate control supports full ISO G-code programming, giving experienced users the power they need.

Multiple Control Options Available

In addition to Fanuc, we also offer:

- Fagor 8058 Elite Conversational Control

- Siemens 828D with ShopTurn

Each option provides intuitive operation and advanced functionality to suit a wide range of operator preferences and manufacturing needs.

Built for Modern Workshops

Every AJAX Superturn machine includes:

- Fully enclosed guarding (CE & UKCA Marked)

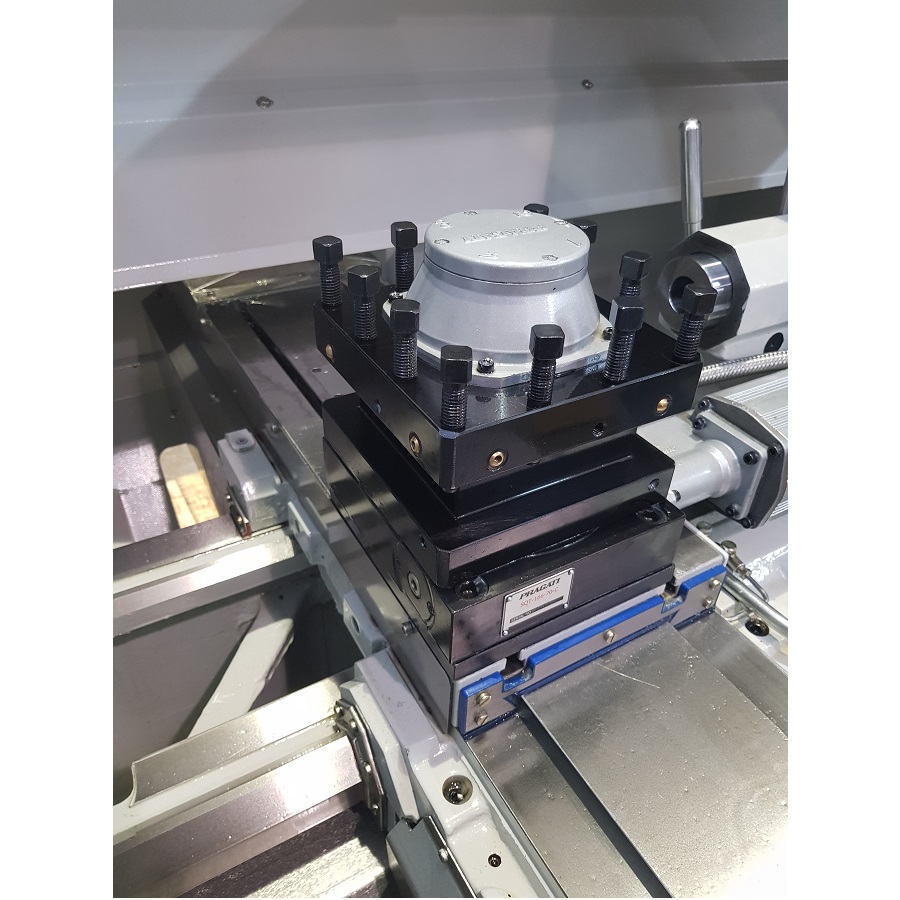

- Automatic 4-way indexing toolpost

- Automatic speed range selection

- Fanuc touchscreen interface with sliding pendant mount

- RS232 and PCMCIA ports for easy program transfer

Whether you’re a small workshop looking to take your first step into CNC or a production facility needing versatility and precision, the AJAX Superturn is a powerful, reliable solution.

Specifications

Turning has become Superturning

The AJAX Superturn offers exceptional versatility across every skill level and application:

- Manual Mode

Operate using electronic handwheels and axis joystick, with the control functioning as a DRO (Digital Readout) system for intuitive, traditional machining. - Electronic Cycle Mode

Perfect for one-off parts and small batches — use Fanuc’s simple conversational interface to quickly produce tapers, radii, grooves, screw threads, and multi-point profiles without needing advanced CNC training. - Full CNC Mode

For more complex parts and higher-volume production, full ISO G-code programming is supported using the Fanuc 0i Plus CNC control.

Electronic cycles can be easily linked to create a complete program, streamlining production without the learning curve.

High Specification as Standard

Every AJAX Superturn lathe is engineered for productivity, safety, and precision:

- Fully enclosed guarding (CE & UKCA marked)

- Automatic 4-way indexing toolpost

- Automatic speed range change

- Fanuc touchscreen monitor on sliding pendant

- Program upload/download via RS232 or directly to PMCIA card

Specifications Overview

- Centre Heights: 200 mm to 300 mm

- Bed Lengths: 750 mm to 2,000 mm

- Spindle Speeds: Vary by model, all with Constant Surface Speed (CSS) as standard

- Drive Systems: Axis and spindle drives powered by Fanuc, ensuring durability and long-term reliability

Control Options Available

- Fanuc 0i TF Turn Mate i

- Fanuc 0i TF Manual Guide i

- Siemens 828D with ShopTurn

- Fagor 8058 Elite Conversational

A New Generation of Performance

The AJAX Superturn series replaces the earlier Evolution, Ultraturn, and Euroturn models—offering higher quality, increased reliability, and enhanced performance to meet the needs of today’s workshops, training centres, and production environments.

Features Include

- Fanuc Touch screen control

- Fagor 8058 Elite control

- Siemens 828D Shopmill control

- Solid cast construction

- High power

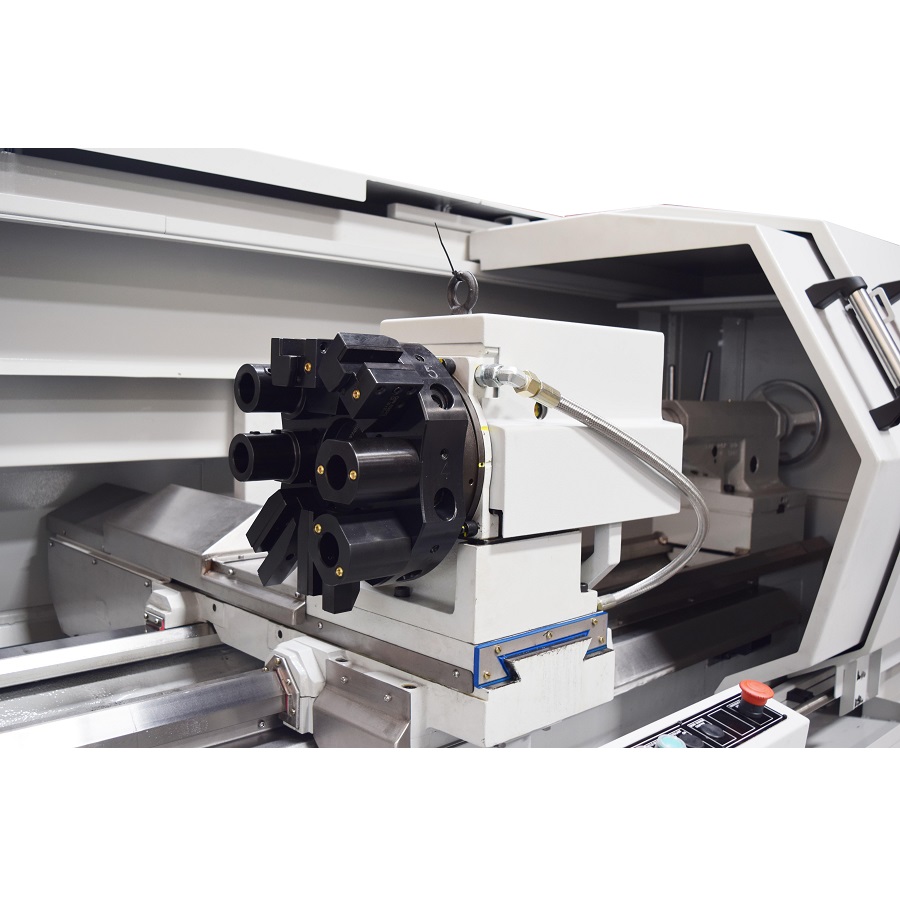

- 4 or 8 station automatic turrets

- Twin handwheels saddle mounted

- Hardened & ground solid ways

Options

- 3 & 4 Jaw chucks,

- Steadies

- Manual Guide i

- Seimens 828D Shopturn

- Fagor 8058 Elite

Standard Features

- Touch screen Fanuc Turn Mate control

- Interlocked guarding & chip collection system

- Coolant equipment

- Automatic lubrication of bed ways

- Electronic hand-wheels or X & Z Axes

- Feed override control

- Digital Fanuc AC spindle Motor

- Digital Fanuc AC Feed drives & motors

- High power lighting

- Fixed centres & reducing bush

- 4 or 8 station turrets

- Instruction Manual

- Hardened bed to 400-450 HB

Options

- 3 & 4 Jaw chucks

- Fixed & travelling steadies

- Live centres

- Face plates

- Manual Guide i

- Siemens 828D Shopmill control

- Fagor 8055 control

Superturn AJST400

Superturn AJST400 AJST600

AJST600 AJAX AJST600 CNC Lathe

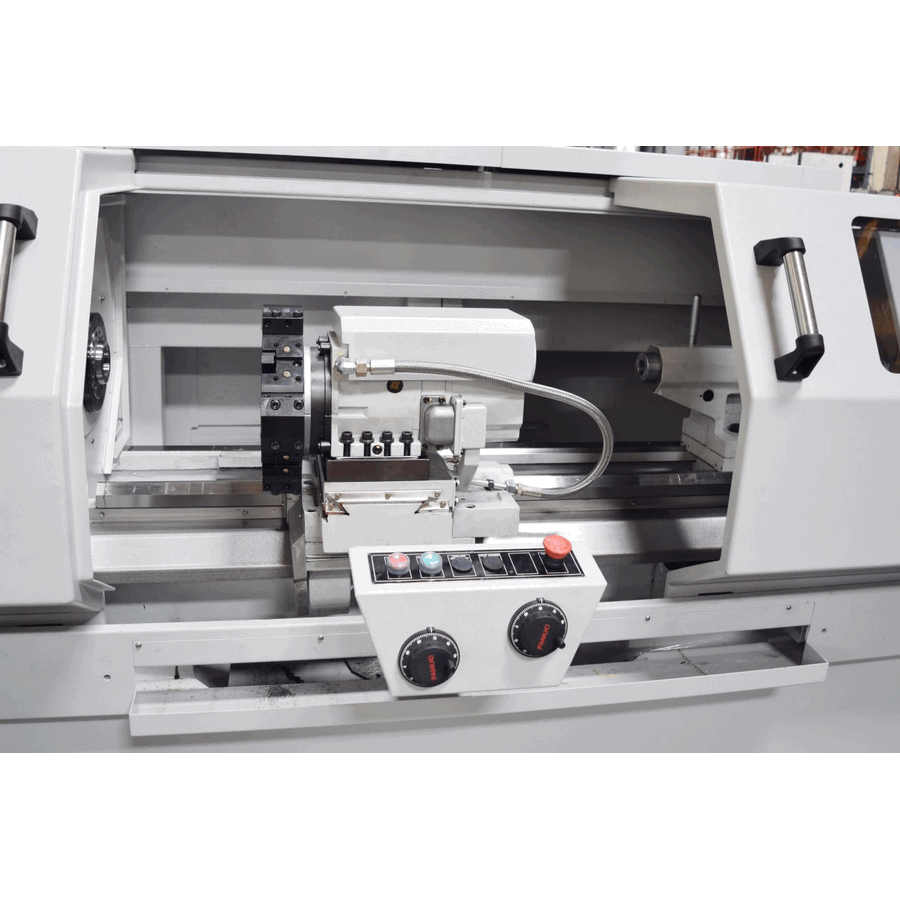

AJAX AJST600 CNC Lathe Ajax AJST400 Doors Open

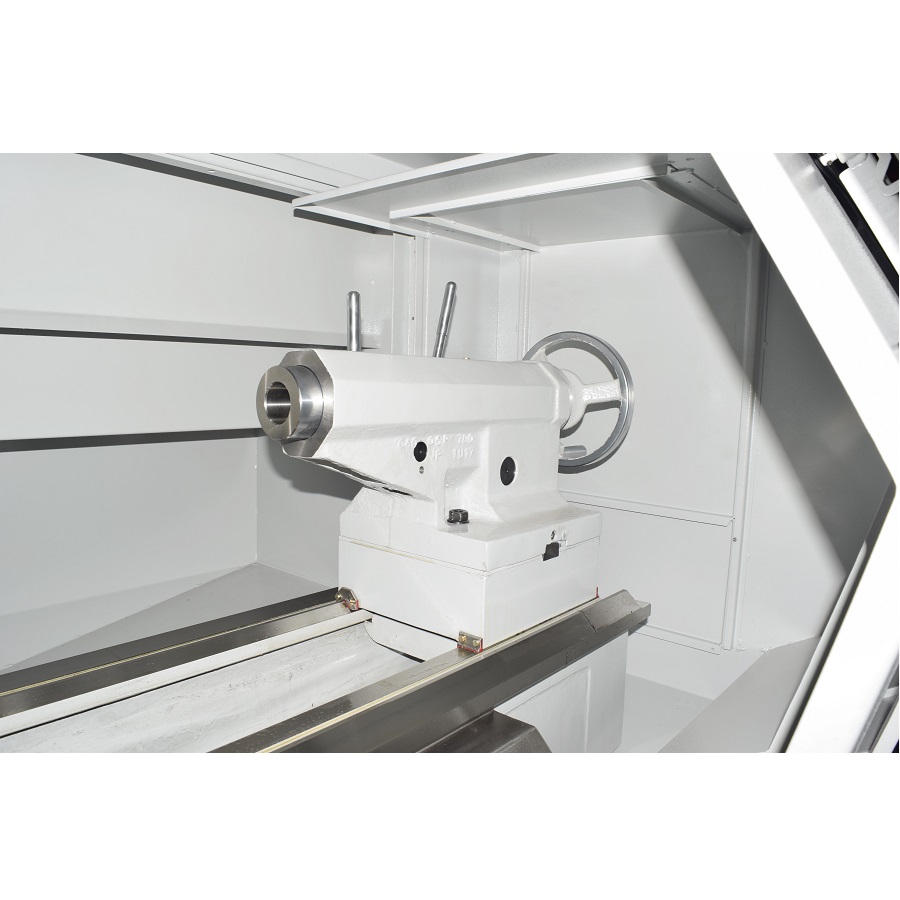

Ajax AJST400 Doors Open AJST600 Tail Stock (Standard)

AJST600 Tail Stock (Standard) Ajax AJST600 VDI Turret

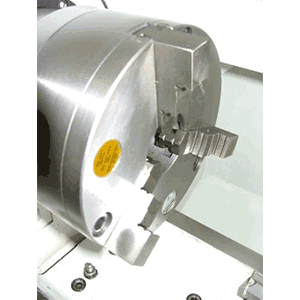

Ajax AJST600 VDI Turret 4 Way Automatic Tool Post (Standard)

4 Way Automatic Tool Post (Standard) Chuck

Chuck

Precision You Can Measure – Backed by Renishaw Laser Technology

At Ajax, precision is not just a promise—it’s a measurable standard. We are proud to be one of the few companies in the UK equipped with the Renishaw XL-80 laser measurement system, a state-of-the-art device capable of detecting motion with nanometre-level accuracy—that’s one-thousandth of a micron or a millionth of a millimetre.

This industry-leading technology allows us to calibrate our machines with extraordinary precision, ensuring they consistently meet the highest performance standards. Calibration can be carried out on-site, and we recommend annual recalibration to maintain peak accuracy and long-term reliability.

Our standard calibration results typically guarantee machine performance within an exceptional tolerance of ±0.002 mm across the entire working envelope. In comparison, many competitors lack both the equipment and capability to verify their tolerances—often relying on unsubstantiated claims rather than proven data.

With Ajax, you’re not just getting machinery—you’re investing in verifiable, certified precision.

Let me know if you’d like this expanded into a full “Quality Assurance” or “Why Choose Ajax” page with visual elements or additional sections on service and support.

Delivery, Installation & Training – We’ve Got You Covered

Our trusted delivery partners can transport and offload your machine using a variety of methods tailored to your site—whether that’s with a Versa-Lift or machine skates for precise positioning.

Once the machine is in place, our fully trained engineers will:

- Level and commission the machine

- Ensure everything is running correctly and safely

- Provide comprehensive training on operation and basic maintenance

From delivery to production, we support you every step of the way.

📞 Get in touch to arrange delivery and installation.