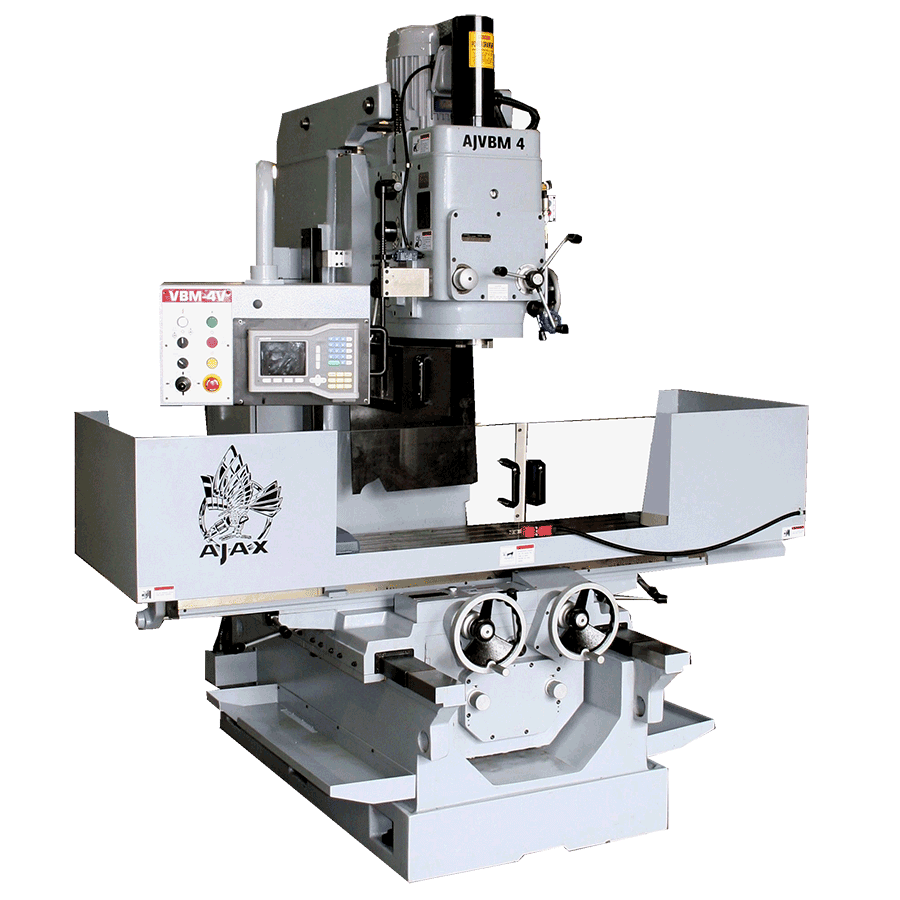

Heavy Duty Milling Machines.

The AJVBM machines are big & heavy duty vertical milling machines, suitable for milling and boring applications. All the axis are driven by low friction ball screws to give better smoother milling with more accuracy. They are pneumatically clamped when not selected. All aur guarded on the table and spindle with interlocks. CE & CA Marked.

Ajax AJVBM machines are large and heavy duty, designed to handle big components with ease. Built & designed by engineers for engineers.

Specifications.

Design.

These machines are ergonomically designed, combining the latest design techniques with the highest standards of quality and engineering. To give good reliability in service. We are happy to say these are the best vertical milling machines on the market today.

Gearboxes.

The AJVBM range has mechanical gearboxes to give the operator a wide range of feeds & speeds. With all gears hardened and ground to last.

Manufacture.

So to make our machines stronger they manufactured with heavy duty ribbed castings. Also the slides are wide giving more cutting stability with an automatic lubrication system to save wear.

Spindle.

The spindle motor has 2 speeds and is driven through a twelve speed gear box to give greater cutting power. The AJVBM8 has an inverter driven spindle to give even more flexibility.

Axis Drives.

To give a wider range of feeds, the axis are driven by an inverter controlled from the pendant. The slied are hardened & ground then Turcite B antifriction material.

Pendant Control.

The machine is controlled from a pendant mounted on an arm. With control of the spindle & axis for ease of use. If selected the DRO is also mounted here.

Optional Extras.

- 2 or 3 axis DRO.

- Clamping Kits.

- Machine vices 100, 150 or 200mm.

- Dividing head.

- Collet holder with collets.

- Boring head.

- Tooling packages.